Nike Alphafly 4 Preview: What To Expect Release Date News & Rumors

🚀 Nike Alphafly 4: What To Expect Release Date News & Rumours

The arrival of the Nike Alphafly 4-codenamed "Nike-Dev 16141"-is shaping up to be one of the most significant footwear launches of 2026, marking a strategic shift in Nike's elite marathon cycle. While the current Alphafly 3 model is still dominating world-class racing, the successor is being positioned to reclaim the title of the "lightest legal super shoe" through substantial re-engineering of the platform, not just an upper refresh. Leaked intelligence points toward a definitive global launch in January 2026, strategically aligning with Japan's high-profile collegiate Ekiden season. This timing maximises the lifecycle of the Alphafly 3, which has seen aggressive UK discounting down to approximately £170.99 - £174.00 at retailers during clearance events, a classic precursor to clearing channel stock for a premium launch. The projected UK retail price for the new Alphafly 4 reflects the continuing inflation of manufacturing costs, sitting between £285.00 and £305.00. Expect the initial "Ekiden Pack" colourway to heavily feature the signature, high-visibility 'Volt' neon green.

Note: This page is a preview based on early news and info and will be updated with a full hands-on review upon launch.

Shin Splints or Runner's Knee?

These aren't just part of running; they are warning signs. See if your current shoe rotation is causing your joint pain. Take the 2-Minute Audit.

The modern marathon is no longer a contest solely of biological endurance; it is a synthesis of human physiology and structural engineering. For the Executive Athlete, the distinction between the body's output and the equipment's efficiency is increasingly negligible. We view the marathon distance not as a spiritual journey, but as a problem of resource management: fuel in, energy out, drag minimised, velocity maintained.

Since 2017, the landscape of distance running has been dictated by a technological arms race. The introduction of high-stack, compliant foam combined with rigid carbon-fibre plates fundamentally altered the physics of the sport. Records have been deleted and rewritten with algorithmic precision. At the apex of this hierarchy sits the Nike Alphafly lineage-the platform responsible for the sub-two-hour marathon.

As we approach the 2026 racing cycle, intelligence gathering from the World Major Marathons indicates the imminent deployment of the fourth iteration: the Nike Alphafly 4. Currently operating under the internal prototype designation Nike-Dev 16141, this unit represents the latest strategic counter-strike in a market where competitors have begun to close the performance gap.

This is not a hype piece. This is a technical audit of the Alphafly 4, analysing its evolution, its structural composition, and its viability as an asset for your next performance cycle.

The Evolution of the Platform

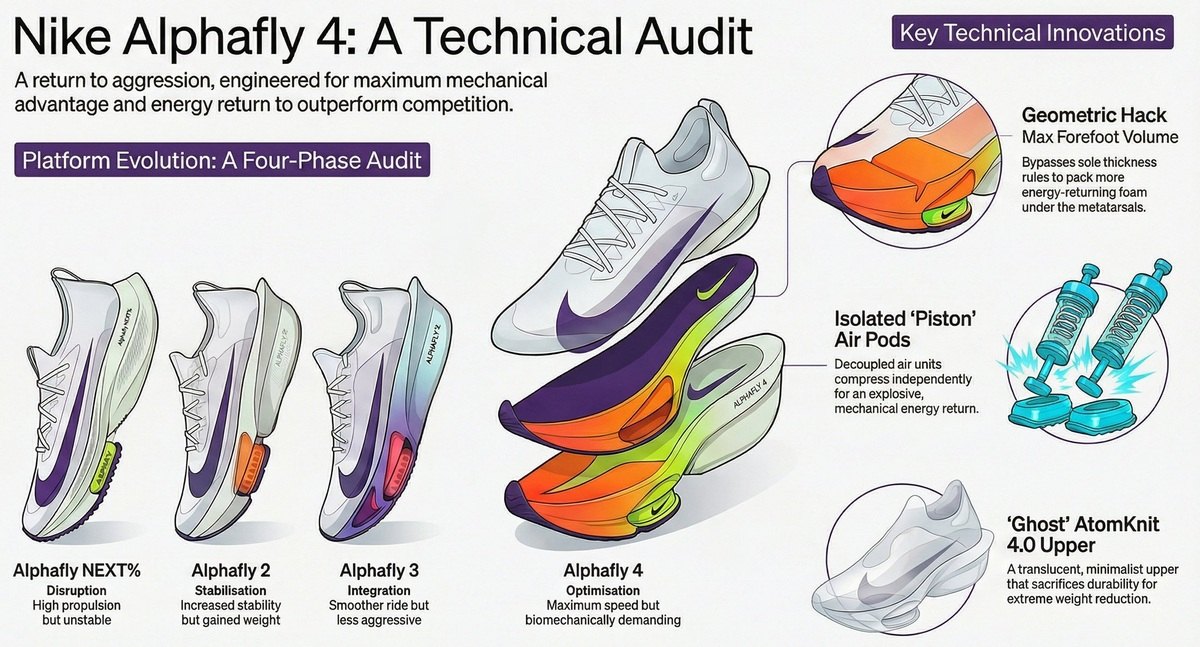

To determine the potential return on investment of the Alphafly 4, one must analyse the iterative development of its predecessors. This lineage is not a fashion statement; it is a series of engineering solutions to biomechanical problems.

Phase 1: The Alphafly NEXT% (Disruption)

The original Alphafly was a radical departure from conventional footwear geometry. It decoupled the forefoot from the heel, inserting two high-volume Zoom Air pods beneath a carbon Flyplate. The objective was purely propulsion. It functioned less like a shoe and more like a leaf spring. The Audit: While propulsive, the narrow chassis created lateral instability. The 4mm offset placed significant structural load on the Achilles complex, requiring a specific, high-velocity gait to operate effectively. It was a volatile asset-high risk, high reward.

Phase 2: The Alphafly 2 (Stabilisation)

The second iteration addressed the volatility of the first. Engineers widened the base width of both the heel and forefoot to create a stable operating platform. The offset was increased to 8mm, reducing the tension on the posterior chain. The Audit: Stability incurred a weight penalty. The added foam volume and reinforced upper structure increased the mass, altering the power-to-weight ratio. It was a reliable cruiser, but it lacked the raw aggression of the original prototype.

Phase 3: The Alphafly 3 (Integration)

Released in early 2024, the Alphafly 3 sought to integrate the benefits of its predecessors. The most significant structural modification was the move to a continuous bottom unit, eliminating the physical gap between the heel and forefoot pods. This harmonised the transition phase of the gait cycle. The Audit: A successful refinement. Weight was reduced, and the transition was smoothed. It served as the platform for the current marathon world record. However, emerging competitor data suggested that "light enough" was no longer the benchmark-absolute weight reduction was required.

Project Nike-Dev 16141: Field Testing and Data Analysis

The Alphafly 4 moved from theoretical design to tangible reality with the appearance of the code Nike-Dev 16141 on the World Athletics approved shoe list. The protocol here is standard: manufacturers must register prototypes for a 12-month development window before mass production. This listing confirms that the stack height and geometry are compliant with Regulation 144.2, but material layups are still undergoing stress testing.

The 2025 Chicago Marathon served as the primary crucible for this new architecture. The resulting data points offer a clear indication of the shoe's performance capabilities.

The Conner Mantz Data Set

American athlete Conner Mantz utilised the Dev 16141 prototype to execute a 2:04:43 finish, establishing a new American Record. This performance broke a benchmark that had remained stagnant for over two decades. The Analysis: Mantz's splits indicate exceptional preservation of running economy. The critical metric is his pace maintenance between the 30km and 35km markers-typically the point of metabolic failure (the "wall"). Mantz accelerated during this phase (2:53/km). This suggests the Alphafly 4 provides superior energy return retention, mitigating the mechanical cost of movement when muscular fatigue sets in. The equipment did not fade.

The Variable Outcomes

Conversely, Sifan Hassan utilised the prototype to a mixed result, finishing 6th. More telling was the decision of the race winner, Jacob Kiplimo, to remain in the Alphafly 3. The Analysis: Elite selection is risk-averse. Kiplimo's refusal to switch suggests the Alphafly 4 represents a significant departure in "handling" characteristics. It likely returns to a more aggressive, less stable geometry. For the Executive Athlete, this is a critical advisory: the Alphafly 4 is likely a more demanding tool than the v3. It requires a robust biomechanical structure to control.

Technical Anatomy: Structural Deconstruction

The Alphafly 4 appears to employ a "geometric hack" to maximise performance within regulatory constraints.

The Regulatory Loophole: Forefoot Volume

World Athletics limits sole thickness to 40mm. However, this measurement is taken at the centre of the heel and the centre of the forefoot. The Strategy: The Alphafly 4 appears to manipulate the geometry by aggressively sculpting the midsole. By potentially lowering the heel-to-toe drop (rumoured to be returning to a lower 4-6mm offset), engineers can pack a higher volume of ZoomX foam into the forefoot while keeping the measured points legal. The Result: A massive reservoir of potential energy under the metatarsals. For the forefoot striker, the shoe effectively behaves like a >40mm unit during the compression phase, offering impact protection that defies the spirit, if not the letter, of the regulation.

Piston Mechanics: Air Zoom Isolation

The midsole sculpting around the forefoot Air Zoom units is more pronounced than in previous iterations. The Mechanism: By removing the foam sidewalls, the pods are decoupled from the sole structure. This allows them to compress vertically without resistance from the surrounding foam, acting as independent pistons. The Benefit: Air units return upwards of 90% of energy. By isolating them, the design maximises their travel and rebound. This creates a more explosive, mechanical "pop" at toe-off, distinct from the dampened return of foam alone.

Weight Reduction: AtomKnit 4.0

To combat the sub-140g offerings from competitors like Adidas, the Alphafly 4 has undergone a severe weight-stripping process. The Construction: The upper is described as extremely translucent. It relies on high-tensile strands for lockdown only at key vector points, abandoning structural mesh in low-stress areas. The outsole rubber is likely minimised to specific contact patches, leaving exposed foam in wear-prone areas. The Trade-off: Durability is sacrificed for performance. This is a race-day asset, not a daily training tool.

Market Context: The Asset Class

The Alphafly 4 does not exist in a vacuum; it is a response to specific market threats.

The Competitor: Adidas Adios Pro Evo 1. The Strategy: Adidas prioritised weight reduction (approx. 138g) over mechanical complexity. The Counter-Strategy: Nike cannot match the weight due to the mass of the Air Zoom units. Therefore, the Alphafly 4 must win on Mechanical Advantage. It must provide enough propulsion to offset its weight penalty. This confirms the hypothesis that the Alphafly 4 will feature a more aggressive rocker and stiffer plate dynamics than the v3. It is designed to do more of the work for you.

Strategic Implementation

For the Strategic Veteran, the Alphafly 4 represents an upgrade in operating conditions.

Operating Parameters:

-

Pace: Optimised for sub-4:00/km paces. At slower speeds, the mechanical stiffness of the plate and the isolated air pods may feel disjointed.

-

Durability: Low. Expect optimal performance for 200-300km. Treat this as a consumable event-day resource.

-

Biomechanics: Demanding. The aggressive rocker and potential lower drop will load the calves and Achilles. Ensure your structural integrity is sufficient before deployment.

The Sundried Roundup

A concise aggregation of intelligence regarding the Nike Alphafly 4.

What are the press saying?

Industry chatter identifies the "Dev 16141" listing as a deliberate leak to generate market anticipation. While prototypes are currently in the field, the standard Nike protocol suggests a retail launch in early 2026, timed to coincide with the Tokyo and London Marathon cycle. Analysts note the confusion with the "Vaporfly 4" (a separate 5k-Half Marathon asset) and emphasise that the Alphafly remains the primary marathon weapon.

What are the review sites saying?

Formal reviews are pending release, but the consensus from biomechanical analysts and prototype observers is that this is a "return to aggression." The "cruiser" feel of the Alphafly 2 and 3 is being replaced by a more radical geometry designed to maximise speed and economy, even at the cost of stability.

What's the history of the shoe and how has it evolved?

-

v1: The Prototype. Sub-2 hour barrier. Unstable, aggressive, high energy return.

-

v2: The Correction. Widened base, increased stability, increased weight.

-

v3: The Refinement. Connected midsole, reduced weight, smoother transition.

-

v4: The Optimisation. Radical sculpting, "piston" pod mechanics, maximal legal forefoot volume.

What can you expect in terms of performance improvement?

Current data indicates an improvement in running economy in the 5-6% range for high responders. The primary performance benefit is Velocity Maintenance: the ability to hold threshold pace late in the race (30km+) due to the mechanical assistance of the Air Zoom/Plate fulcrum reducing the metabolic cost per step.

Special features

-

Geometric Hack: Utilising distinct measurement points to pack >40mm effective volume of foam into the forefoot.

-

Decoupled Piston Pods: Removing sidewalls to allow independent vertical compression of Air units.

-

AtomKnit 4.0: A translucent, high-tensile upper structure focused solely on lockdown with zero excess mass.

Comfort features?

Comfort is secondary to output. The upper is stripped of padding to save weight. The ride will be firm and responsive rather than "plush." Do not expect a cushioned heel collar; expect a minimal structural hold. Pain is data; if the shoe generates blisters but saves 2 minutes, the trade is efficient.

Top 5 Features

Independent "Piston" Air Zoom Units

Maximised vertical compression for explosive energy return.

Aggressive Forefoot Rocker

A steep fulcrum geometry to minimise ground contact time.

"Ghost" AtomKnit Upper

Ultra-minimalist material reducing weight and water retention.

Max-Volume Forefoot Stack

Optimised foam volume for impact protection under the metatarsals.

Targeted Traction Pattern

Outsole rubber placed only at elite stride contact points to reduce rotational mass.

Ditch the "Couch to 5k" PDF

Generic plans don't know your injury history or your gear. Get a personalized analysis based on your unique runner profile. Start Your Custom Profile.